2017-2020 R6 Installation Instructions for:

Frame Sliders

Fork Sliders

Rear Axle Sliders

Swingarm Spools

WARNING: The installation of all parts in these installation instructions must be performed by a qualified motorcycle mechanic who is using the correct tools and who understands the correct use of all tools required to complete the installation.

Frame Sliders

Tools/Items Needed:

Torque wrench

1/2" drive ratchet

12mm socket

5mm Allen wrench

4mm Allen wrench

8mm Allen driver

Phillips screwdriver (small)

Blue Loctite

Not necessary but a helper is nice to have for this installation.

Frame Sliders

Fork Sliders

Rear Axle Sliders

Swingarm Spools

WARNING: The installation of all parts in these installation instructions must be performed by a qualified motorcycle mechanic who is using the correct tools and who understands the correct use of all tools required to complete the installation.

Frame Sliders

Tools/Items Needed:

Torque wrench

1/2" drive ratchet

12mm socket

5mm Allen wrench

4mm Allen wrench

8mm Allen driver

Phillips screwdriver (small)

Blue Loctite

Not necessary but a helper is nice to have for this installation.

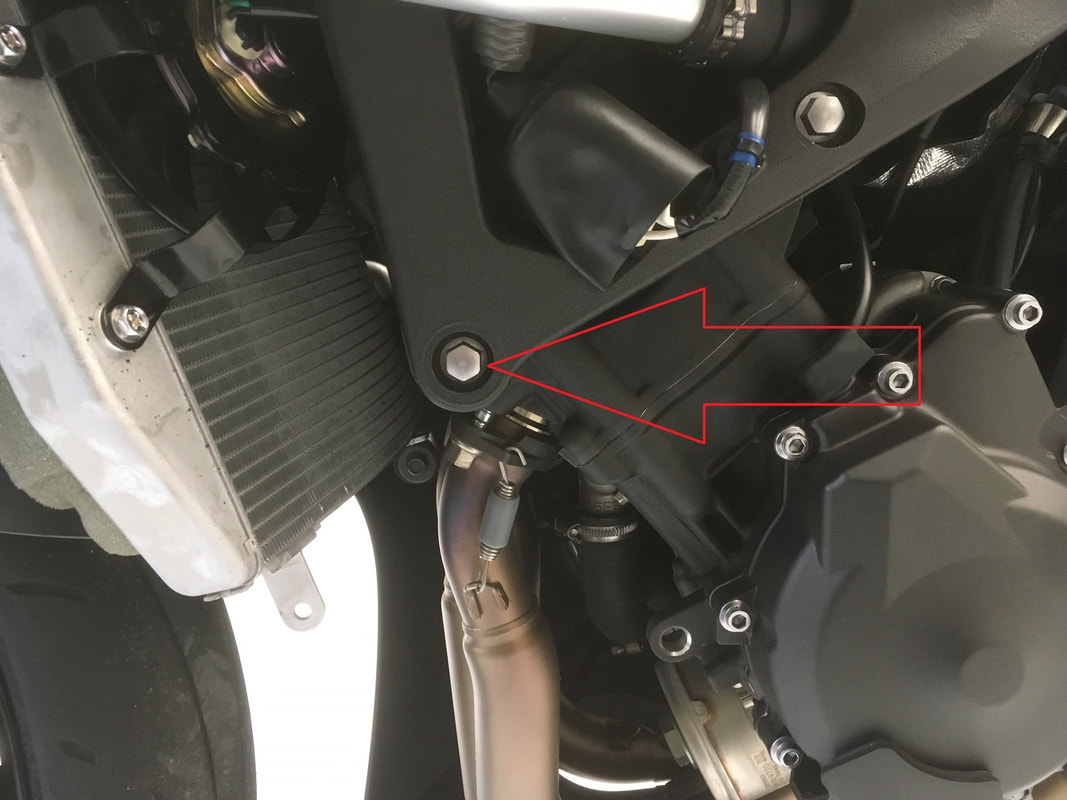

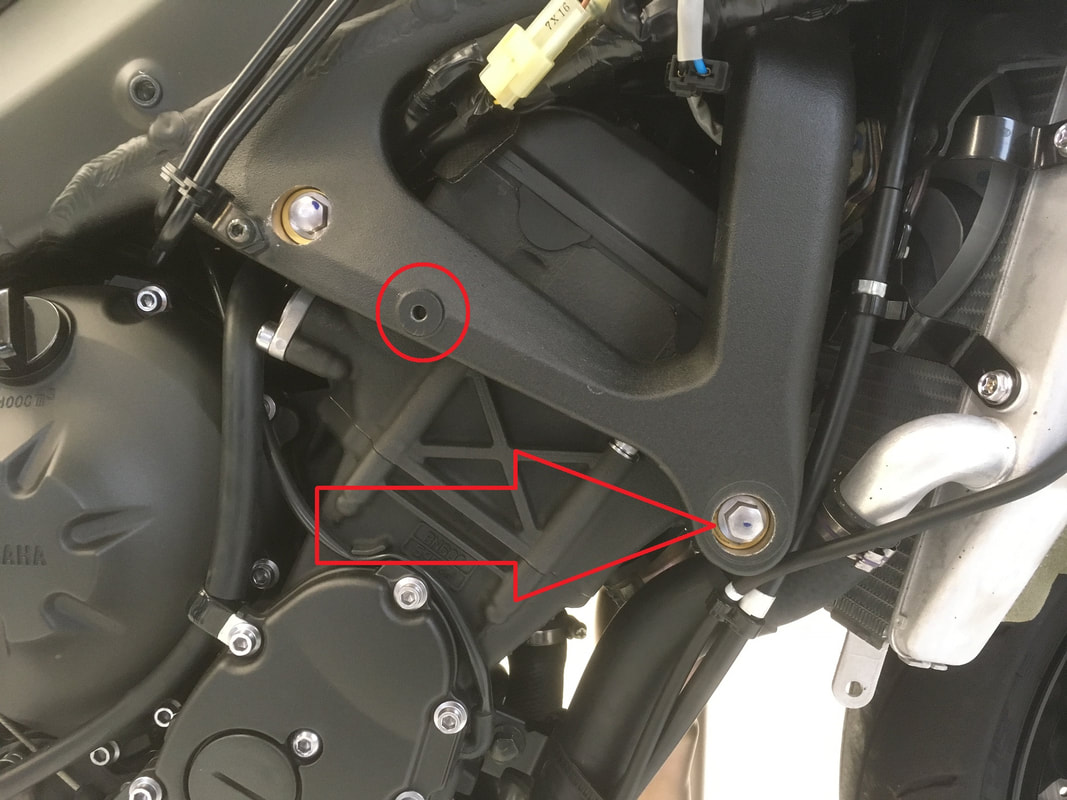

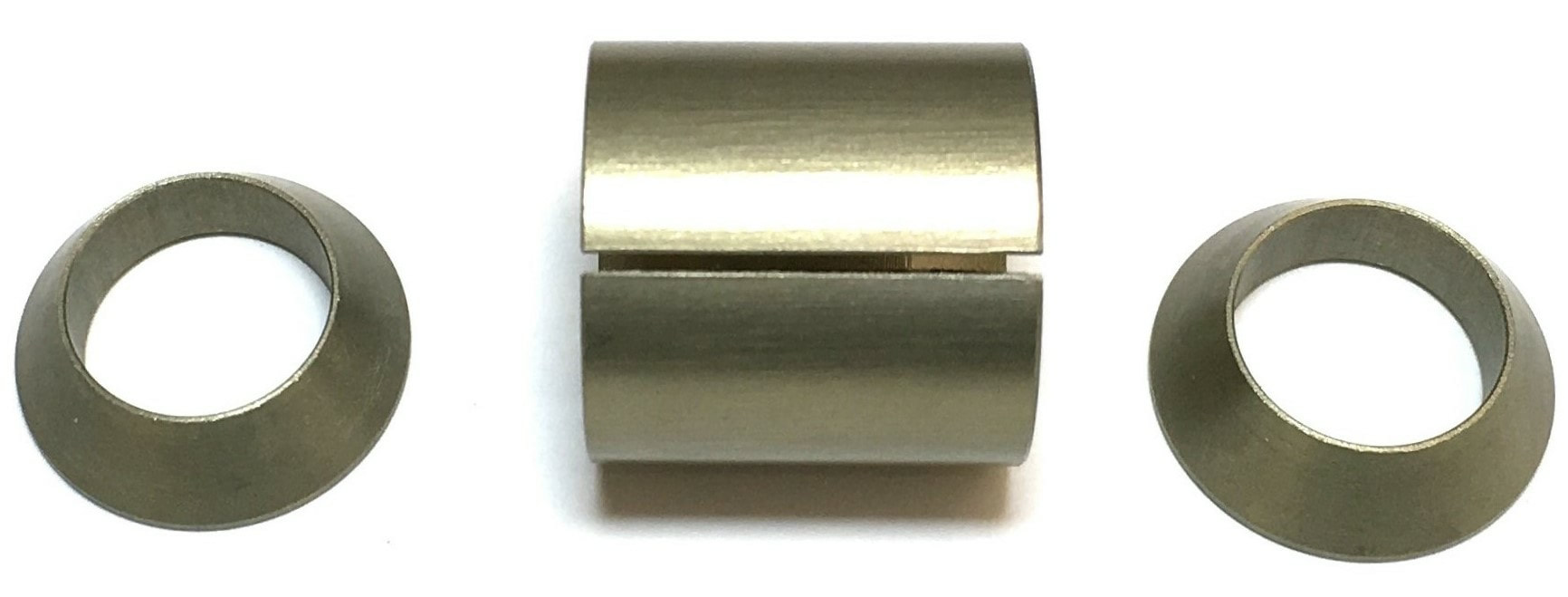

16. The left side frame slider is slightly shorter than the right side. Apply a small amount of blue loctite to left side frame slider mounting screw and tighten to the bracket using 35 lb/ft of torque. Even when fully tightened, the slider may turn on its spacer with force but this is normal.

17. Repeat step 16 with the right side slider, the longest of the two.

Finish this installation by checking that all fairing screws and pins are tight and in place and that both frame slider mounting screws have been final-tightened.

Please contact us with questions about this installation.

If a frame slider or bracket is damaged in a crash or drop you can purchase just the side you need on this site.

17. Repeat step 16 with the right side slider, the longest of the two.

Finish this installation by checking that all fairing screws and pins are tight and in place and that both frame slider mounting screws have been final-tightened.

Please contact us with questions about this installation.

If a frame slider or bracket is damaged in a crash or drop you can purchase just the side you need on this site.