2017-2020 R6 Installation Instructions for:

Frame Sliders

Fork Sliders

Rear Axle Sliders

Swingarm Spools

Frame Sliders

Tools/Items Needed:

1/2" drive ratchet

12mm socket

5mm Allen wrench

4mm Allen wrench

8mm Allen driver

Phillips screwdriver (small)

Blue Loctite

Not necessary but a helper is nice to have for this installation.

1. Remove the trim piece in figure A by removing the two push-pins on the trim piece. The pins will unlock and remove by depressing the center of each with a small screwdriver tip.

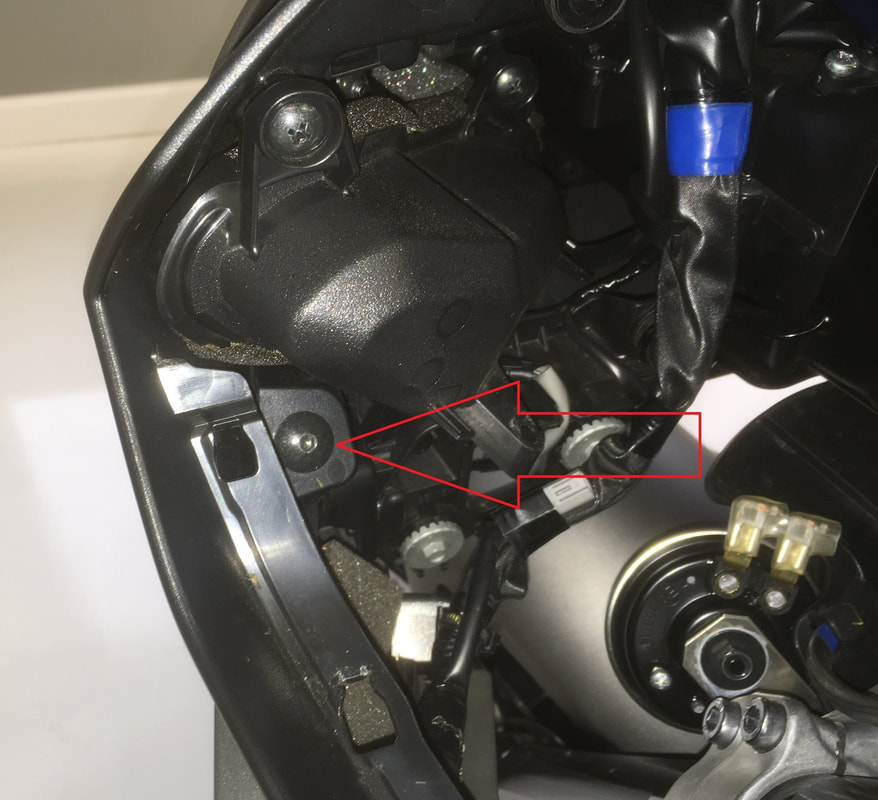

CAUTION: The trim piece has a pin (not a push-pin) that holds it to a bracket. That pin (see figure A2) is located at the end of the piece near the frame. A lifting force needs to be applied near the pin to free it from the bracket. If the piece is lifted from the front DAMAGE TO THE TRIM PIECE WILL OCCUR.

For easy removal after the pin disconnects from the bracket, the piece needs to be shifted backward slightly, then tilted out.

2. The trim piece in figure B will also need to be removed. It has four push-pins (only two are visible in the photo).

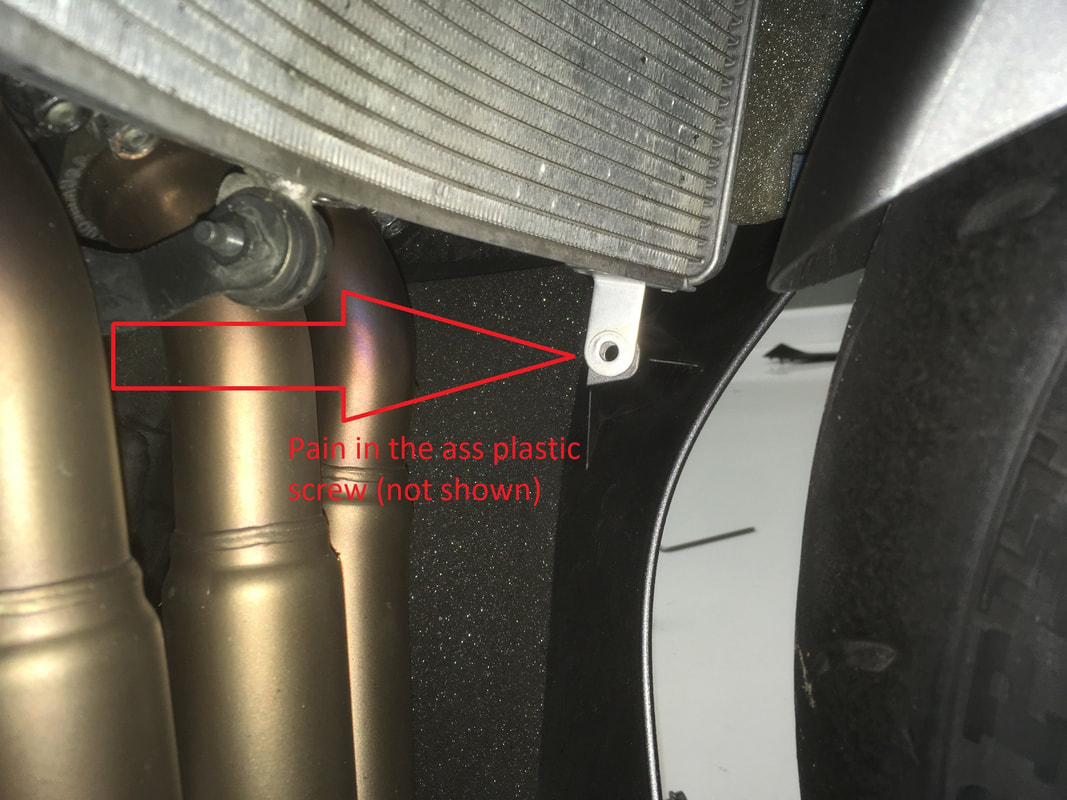

3. After that, you'll need to remove the pain in the ass plastic screw that holds the fairing to the radiator. That attachment point is seen in figure C. The screw is not shown.

Yours might not give you trouble but if it does we recommend using a small screwdriver and very light pressure to unscrew it. You also might need to hold the outermost part of the flange to prevent it from turning. We'll gladly revise these instructions to include any other tricks to remove the screw if submitted.

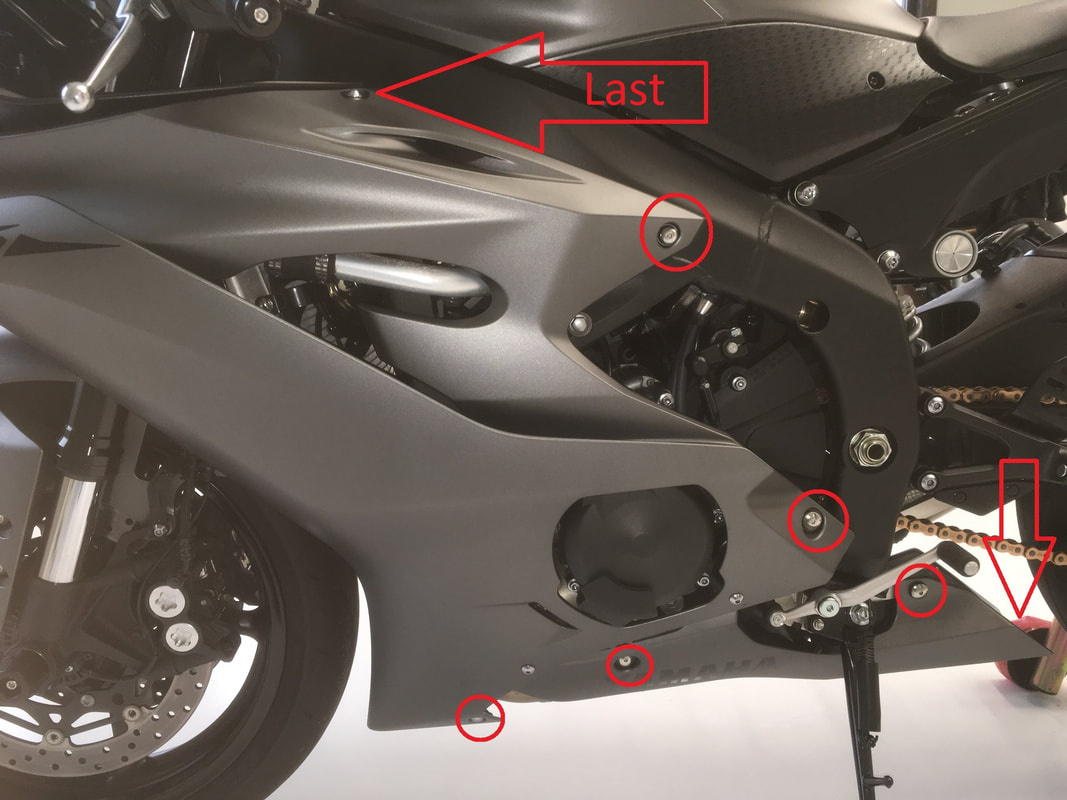

4. Except the screw at the arrow point labeled 'Last', remove each fairing screw at all other circled points (figure D and E). The arrow pointing down is to a screw that connects the left and right fairings at the rear.

5. After the screws are removed, the forward lower point of the fairings (very close to front tire) will still be held to the right side fairing by a black connector piece. Hold the left fairing and push backward on the black piece and it will disconnect from the left fairing.

6. Remove the last screw and support the fairing at that point while pulling firmly in the area shown in figure E.

CAUTION: The fairing could possibly be damaged if your pulling force is not applied to the specified area. The connection is tight but a firm pull outward will free it.

Figure F shows the tab on the fairing that needs to be freed to complete the fairing removal.

7. The right side fairing can be removed using the same sequence, however,

- A trim piece for the right side that is similar to the piece removed in step two has only three push-pins, instead of four.

- The screw holding the black connector piece mentioned in step five can remain in place since the connector piece does not need to be removed from the right side fairing.

Installing the frame sliders should be done only one side at a time.

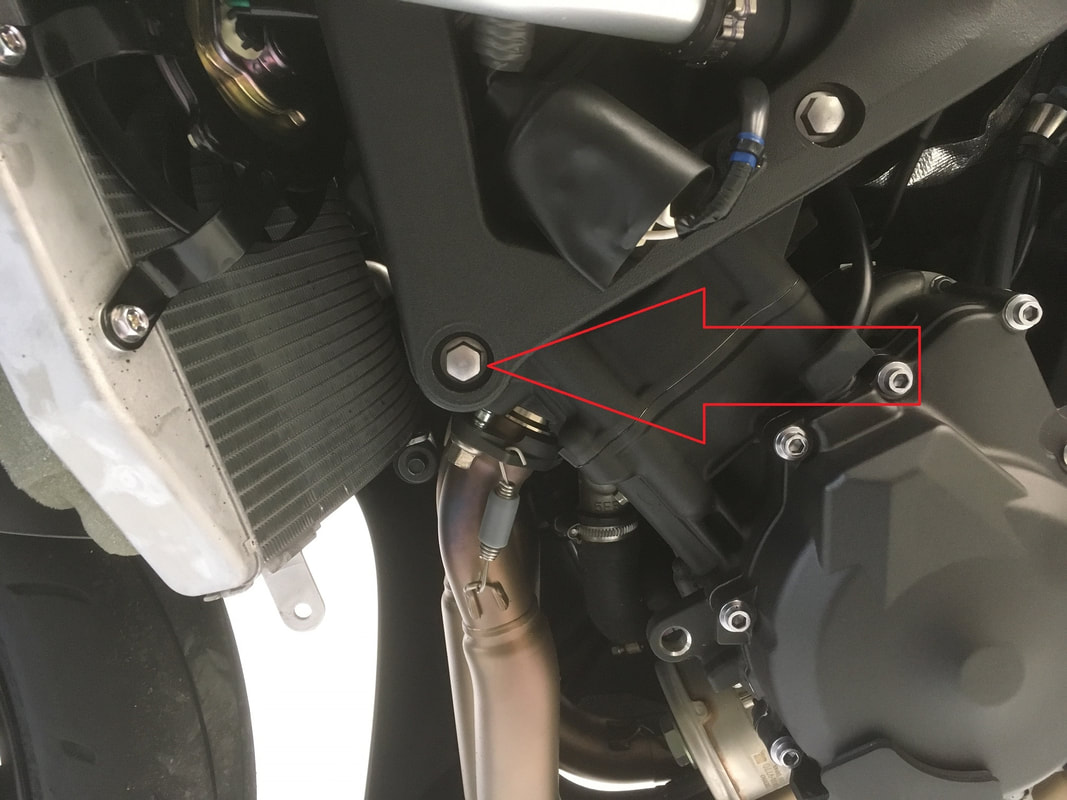

8. With your 12mm socket and ratchet, remove the engine mount screw in figure H.

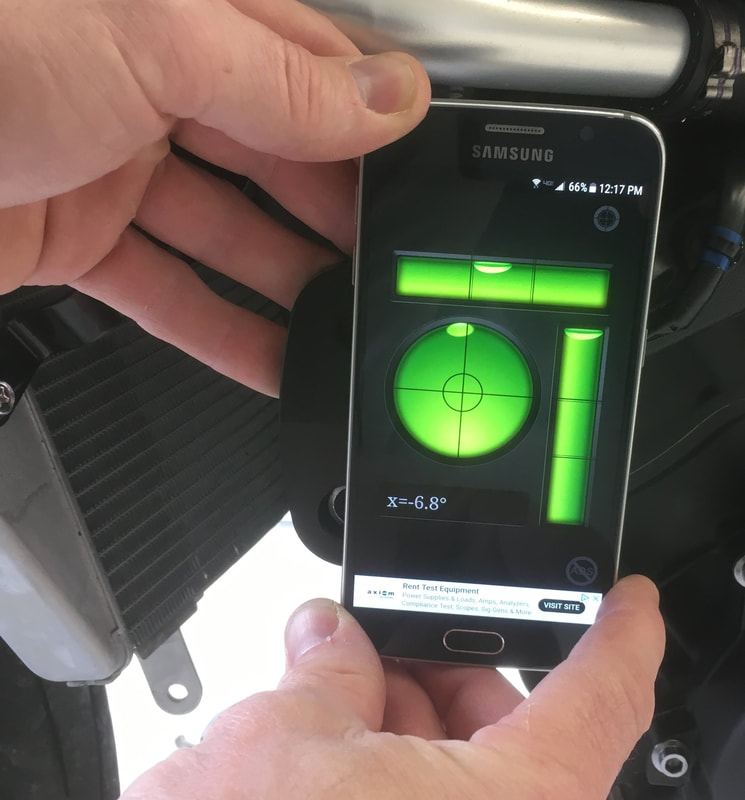

9. Install the offset bracket so that it is not completely tight but able to be adjusted by hand (figure I). The bracket should be near the 12 o'clock position as seen in figure J. A level or a phone with a level app is good to use, as seen here. Get it as close to the one in the picture but do not final tighten it yet since a small amount of adjustment might be necessary. The bike in the photo is sitting level on the floor and is being held upright by a helper.

10. Figure J shows an area of the inside of the left fairing that needs a small section of the foam removed from it. When installed, the fairing is very close to the frame slider offset bracket; foam left in this area will cause the fairing to bulge outward when mounted.

11. In this step and final assembly, the section at the top of the fairing near the frame needs to be properly seated. The black piece at the top edge of the fairing needs to be connected to the fairing completely. It's more accurate to connect the black piece to the fairing first, then put the fairing in place as seen in figure I. The mounting point should look just like the one in the photo- if not, the fairing will not tighten correctly at this point.

12. Attach the fairing, then adjust the bracket as needed to avoid contact with the fairing.

13. Remove the fairing.

14. Final tighten the frame slider mounting bracket.

Frame Sliders

Fork Sliders

Rear Axle Sliders

Swingarm Spools

Frame Sliders

Tools/Items Needed:

1/2" drive ratchet

12mm socket

5mm Allen wrench

4mm Allen wrench

8mm Allen driver

Phillips screwdriver (small)

Blue Loctite

Not necessary but a helper is nice to have for this installation.

1. Remove the trim piece in figure A by removing the two push-pins on the trim piece. The pins will unlock and remove by depressing the center of each with a small screwdriver tip.

CAUTION: The trim piece has a pin (not a push-pin) that holds it to a bracket. That pin (see figure A2) is located at the end of the piece near the frame. A lifting force needs to be applied near the pin to free it from the bracket. If the piece is lifted from the front DAMAGE TO THE TRIM PIECE WILL OCCUR.

For easy removal after the pin disconnects from the bracket, the piece needs to be shifted backward slightly, then tilted out.

2. The trim piece in figure B will also need to be removed. It has four push-pins (only two are visible in the photo).

3. After that, you'll need to remove the pain in the ass plastic screw that holds the fairing to the radiator. That attachment point is seen in figure C. The screw is not shown.

Yours might not give you trouble but if it does we recommend using a small screwdriver and very light pressure to unscrew it. You also might need to hold the outermost part of the flange to prevent it from turning. We'll gladly revise these instructions to include any other tricks to remove the screw if submitted.

4. Except the screw at the arrow point labeled 'Last', remove each fairing screw at all other circled points (figure D and E). The arrow pointing down is to a screw that connects the left and right fairings at the rear.

5. After the screws are removed, the forward lower point of the fairings (very close to front tire) will still be held to the right side fairing by a black connector piece. Hold the left fairing and push backward on the black piece and it will disconnect from the left fairing.

6. Remove the last screw and support the fairing at that point while pulling firmly in the area shown in figure E.

CAUTION: The fairing could possibly be damaged if your pulling force is not applied to the specified area. The connection is tight but a firm pull outward will free it.

Figure F shows the tab on the fairing that needs to be freed to complete the fairing removal.

7. The right side fairing can be removed using the same sequence, however,

- A trim piece for the right side that is similar to the piece removed in step two has only three push-pins, instead of four.

- The screw holding the black connector piece mentioned in step five can remain in place since the connector piece does not need to be removed from the right side fairing.

Installing the frame sliders should be done only one side at a time.

8. With your 12mm socket and ratchet, remove the engine mount screw in figure H.

9. Install the offset bracket so that it is not completely tight but able to be adjusted by hand (figure I). The bracket should be near the 12 o'clock position as seen in figure J. A level or a phone with a level app is good to use, as seen here. Get it as close to the one in the picture but do not final tighten it yet since a small amount of adjustment might be necessary. The bike in the photo is sitting level on the floor and is being held upright by a helper.

10. Figure J shows an area of the inside of the left fairing that needs a small section of the foam removed from it. When installed, the fairing is very close to the frame slider offset bracket; foam left in this area will cause the fairing to bulge outward when mounted.

11. In this step and final assembly, the section at the top of the fairing near the frame needs to be properly seated. The black piece at the top edge of the fairing needs to be connected to the fairing completely. It's more accurate to connect the black piece to the fairing first, then put the fairing in place as seen in figure I. The mounting point should look just like the one in the photo- if not, the fairing will not tighten correctly at this point.

12. Attach the fairing, then adjust the bracket as needed to avoid contact with the fairing.

13. Remove the fairing.

14. Final tighten the frame slider mounting bracket.

1. Remove the trim piece in figure A by removing the two push-pins on the trim piece. The pins will unlock and remove by depressing the center of each with a small screwdriver tip.

CAUTION: The trim piece has a pin (not a push-pin) that holds it to a bracket. That pin (see figure A2) is located at the end of the piece near the frame. A lifting force needs to be applied near the pin to free it from the bracket. If the piece is lifted from the front DAMAGE TO THE TRIM PIECE WILL OCCUR.

For easy removal after the pin disconnects from the bracket, the piece needs to be shifted backward slightly, then tilted out.

CAUTION: The trim piece has a pin (not a push-pin) that holds it to a bracket. That pin (see figure A2) is located at the end of the piece near the frame. A lifting force needs to be applied near the pin to free it from the bracket. If the piece is lifted from the front DAMAGE TO THE TRIM PIECE WILL OCCUR.

For easy removal after the pin disconnects from the bracket, the piece needs to be shifted backward slightly, then tilted out.

Figure A2

Figure A2

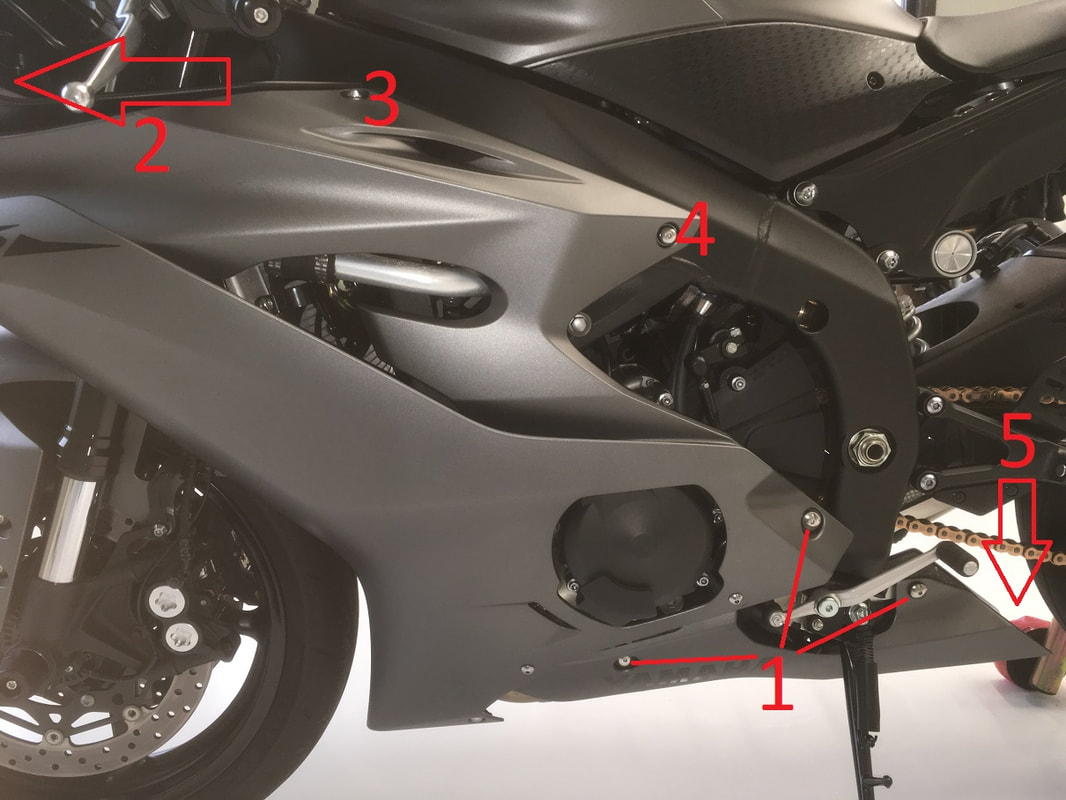

4. Except for the screw at the arrow point labeled 'Last', remove each fairing screw at all other circled points (figure D and E). The arrow pointing down is to a screw that connects the left and right fairings at the rear.

5. After the screws are removed, the forward lower point of the fairings (very close to front tire) will still be held to the right side fairing by a black connector piece. Hold the left fairing and push backward on the black piece and it will disconnect from the left fairing.

5. After the screws are removed, the forward lower point of the fairings (very close to front tire) will still be held to the right side fairing by a black connector piece. Hold the left fairing and push backward on the black piece and it will disconnect from the left fairing.

6. Remove the last screw and support the fairing at that point while pulling firmly in the area shown in figure F.

CAUTION: The fairing will be damaged if your pulling force is not applied to the specified area. The connection is tight but a firm pull outward will free it. Figure G below shows the tab on the fairing that needs to be freed to complete the fairing removal.

7. The right side fairing can be removed using the same sequence, however,

- A trim piece for the right side that is similar to the piece removed in step two has only three push-pins, instead of four.

- The screw holding the black connector piece mentioned in step five can remain in place since the connector piece does not need to be removed from the right side fairing.

CAUTION: The fairing will be damaged if your pulling force is not applied to the specified area. The connection is tight but a firm pull outward will free it. Figure G below shows the tab on the fairing that needs to be freed to complete the fairing removal.

7. The right side fairing can be removed using the same sequence, however,

- A trim piece for the right side that is similar to the piece removed in step two has only three push-pins, instead of four.

- The screw holding the black connector piece mentioned in step five can remain in place since the connector piece does not need to be removed from the right side fairing.

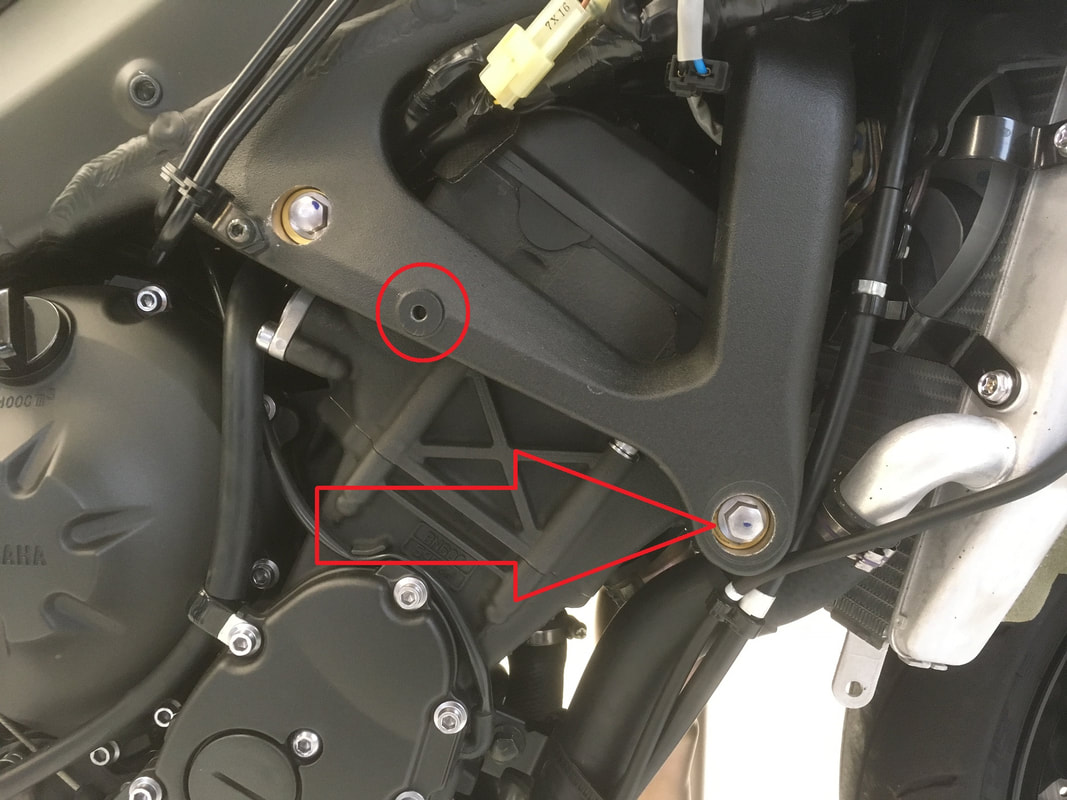

8. With your 12mm socket and ratchet, remove the engine mount screw in figure H. No other engine mount screw should be removed while this one is out.

9. Install the offset bracket so that it is slightly past the 12 o'clock position as seen in figure J. A level or a phone with a level app is good to use, as seen here. The bike in the photo is sitting level on the floor and is being held upright by a helper. Once the correct position is achieved, the screw can be final tightened. The bracket will try to turn but holding it will prevent it from doing so.

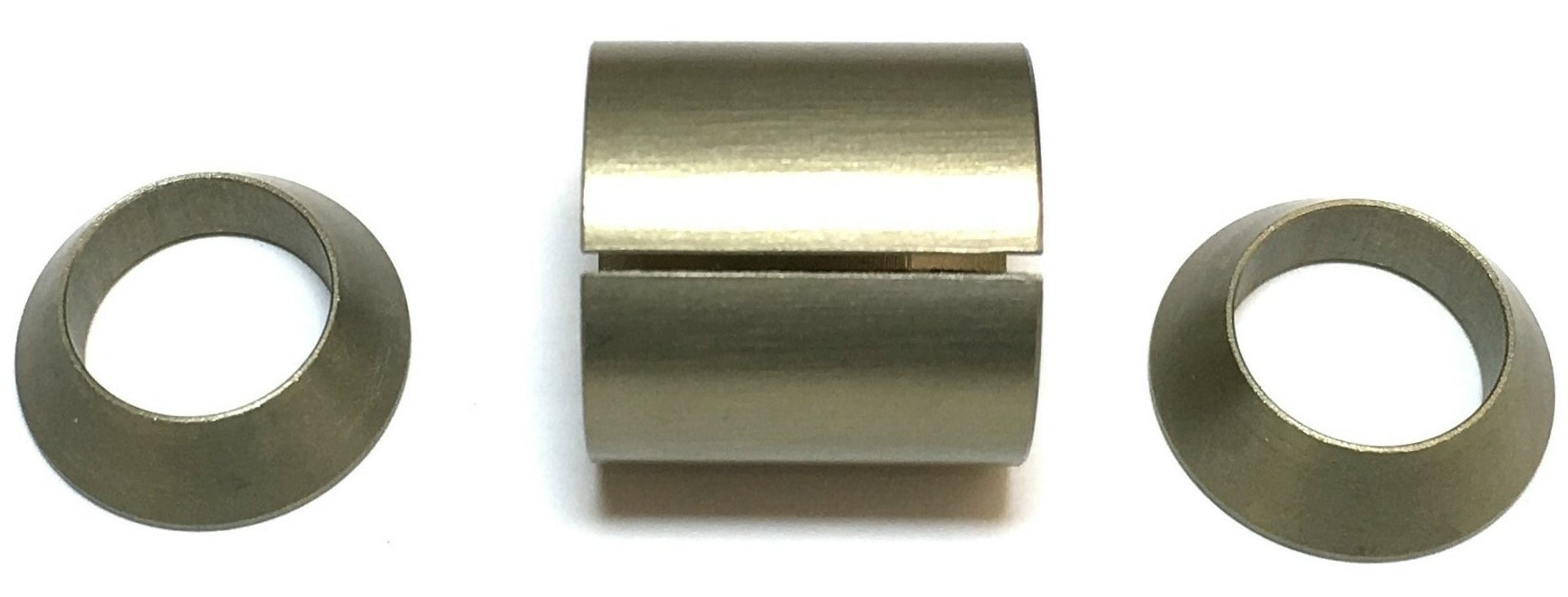

10. The right side fairing should have already been removed in step 7, so the engine mount screw at the arrow point can be removed. With your 12mm socket and ratchet, remove the engine mount screw. No other engine mount screw should be removed while this one is out. CAUTION! Do not remove the spacer set under the mount screw- it must remain in place. If the spacer set is missing for any reason, do not proceed until a spacer set is installed. A spacer set is shown below for reference if there is any concern of a missing spacer set.

10. The right side fairing should have already been removed in step 7, so the engine mount screw at the arrow point can be removed. With your 12mm socket and ratchet, remove the engine mount screw. No other engine mount screw should be removed while this one is out. CAUTION! Do not remove the spacer set under the mount screw- it must remain in place. If the spacer set is missing for any reason, do not proceed until a spacer set is installed. A spacer set is shown below for reference if there is any concern of a missing spacer set.

16. The supplied frame slider bracket and bracket spacer is shown above. Hand tighten the mounting screw.

17. Attach the other end of the bracket as seen in the photo below and hand tighten the screw.

18. Use your 8mm Allen driver and ratchet to tighten the slider bracket/engine mount screw. If using a torque wrench, tighten to 35 lbs/ft.

19. Use a 5mm Allen wrench to tighten the small mounting screw. Over torquing the screw will snap it. - We do not have an inch or ft/lb spec for this screw, however, a torque angle of around 45 degrees will be sufficient.

17. Attach the other end of the bracket as seen in the photo below and hand tighten the screw.

18. Use your 8mm Allen driver and ratchet to tighten the slider bracket/engine mount screw. If using a torque wrench, tighten to 35 lbs/ft.

19. Use a 5mm Allen wrench to tighten the small mounting screw. Over torquing the screw will snap it. - We do not have an inch or ft/lb spec for this screw, however, a torque angle of around 45 degrees will be sufficient.

Installing the fairings

10. Figure J shows an area of the inside of the left fairing that needs a small section of the foam removed from it. When installed, the fairing is very close to the frame slider offset bracket; foam left in this area will cause the fairing to bulge outward when mounted.

Just in case you forgot where each fairing screw is supposed to go, use the two photos below for reference.

10. Figure J shows an area of the inside of the left fairing that needs a small section of the foam removed from it. When installed, the fairing is very close to the frame slider offset bracket; foam left in this area will cause the fairing to bulge outward when mounted.

Just in case you forgot where each fairing screw is supposed to go, use the two photos below for reference.

10. Install the left side fairing. Push on the area shown in figure H to clear the mounting bracket, then move the fairing forward.

11. In this step, the section at the top of the fairing near the frame needs to be properly seated. The black piece at the top edge of the fairing needs to be connected to the fairing completely. It's more accurate to connect the black piece to the fairing first, then put the fairing in place as seen in figure I above. The black piece has a tab that is sandwiched between the fairing and its mounting bracket. The mounting point should look just like the one in the photo- if not, the fairing will not tighten correctly here.

12. After the fairings are completely installed, attach a frame slider to each bracket. The shorter slider goes on the left side.

WARNING: THE WASHERS MUST BE ON THE SCREWS BEFORE INSTALLING THE SLIDERS. EACH SCREW MUST HAVE BLUE THREAD LOCKER ON IT. TORQUE TO 30 LBS/FT.

Replacement sliders and/or brackets are available on this site.

12. After the fairings are completely installed, attach a frame slider to each bracket. The shorter slider goes on the left side.

WARNING: THE WASHERS MUST BE ON THE SCREWS BEFORE INSTALLING THE SLIDERS. EACH SCREW MUST HAVE BLUE THREAD LOCKER ON IT. TORQUE TO 30 LBS/FT.

Replacement sliders and/or brackets are available on this site.